Motores sin Escobillas

- Motores sin Escobillas Sistemas de Control de Velocidad CA

- Motores sin Escobillas Sistemas de Control de Velocidad CC

Atuadores Lineares

- Atuadores Lineares - Guías Lineales Motorizadas

- Atuadores Lineares - Cilindros Lineales Motorizados

- Atuadores Lineares Compactos

- Atuadores Lineares (Actuadores Únicamente)

- Controladores / Productos de Red

Actuadores Hiratorios Huecos

CAD / Búsqueda Manual

Para encontrar CAD y Manuales de Operador de nuestros products, por favor realice la búsqueda usando el número de item

![]()

Para Inglés o Español:

Para japonés:

Clientes de Mexíco:

Servicio Al Cliente - +001-847-871-5931

Soporte técnico - 800-681-5309

Clientes Internacionales:

+1-847-871-5931 o

+1-310-715-3304

Para soporte en productos del catálogo japonés:

1-800-746-6872 o

+1-310-715-3304

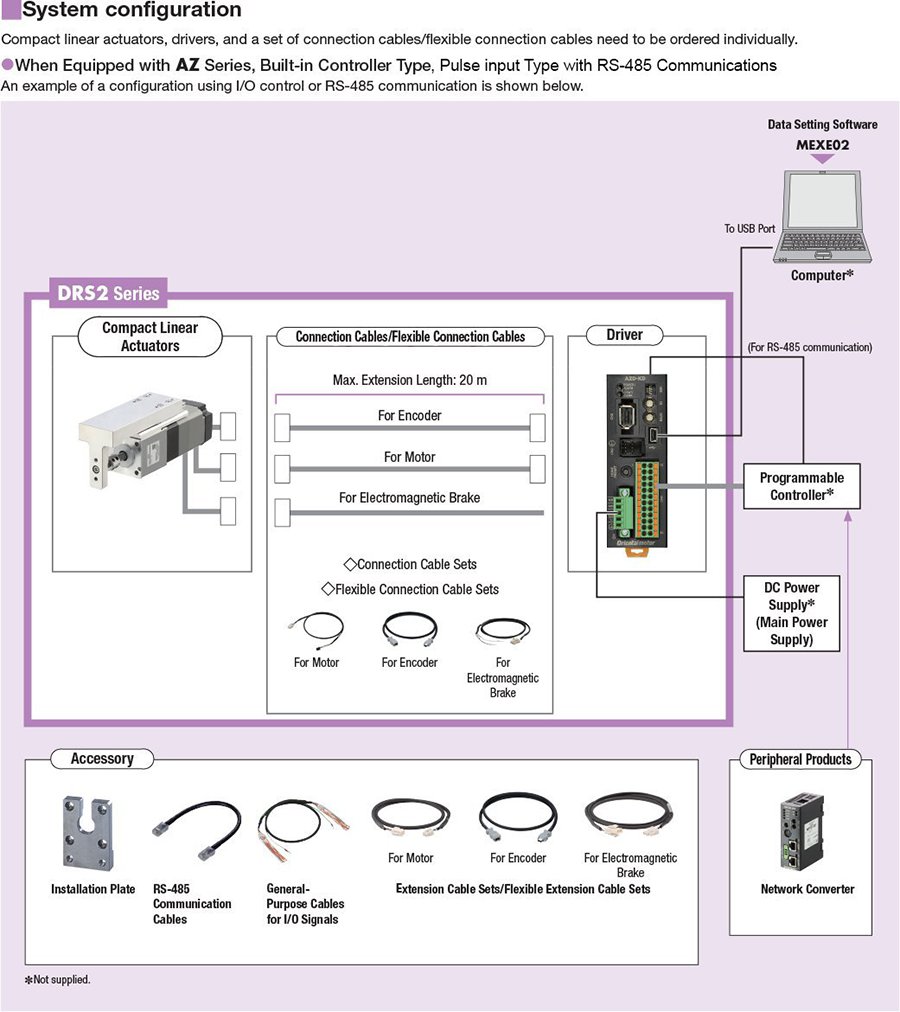

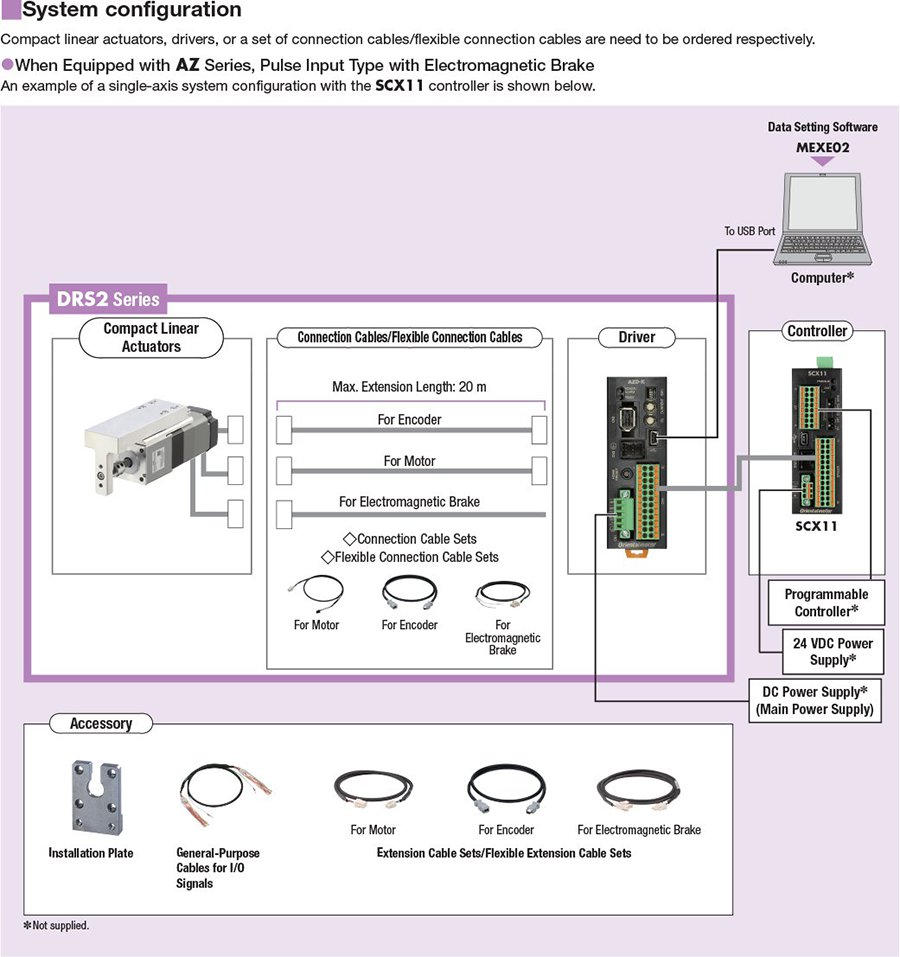

DRS2 Series Compact Linear Actuators

DRS2 Series Compact Linear Actuators

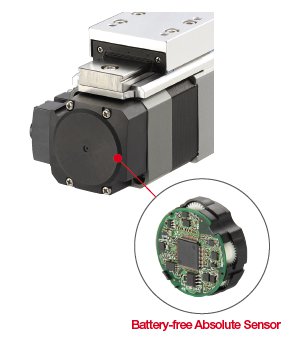

The DRS2 Series uses the AZ Series motor and driver. The actuator is equipped with the Mechanical Absolute Encoder. The Absolute Encoder is a mechanical multi-turn Absolute Sensor, so an external sensor is not required. This helps to save space and reduce wiring, as well as more compact and lightweight design of the equipment. Actuator is available with or without a Guide. Electromechanical Brake, and Rolled or Ground ball screws.

Built-in Controller (Stored Data) allows for easy networking and simplified multi-axis control.

- AZ Series Absolute Encoder Motor

- Built-in Controller (Network Type), Pulse Input Type or Pulse Input Type with RS-485 Communications Drivers

- 24/48 VDC Input

- Repetitive Positioning Accuracy

- Ground Ball Screw = ±0.003 mm

- Rolled Ball Screw = ±0.01 mm

Mechanical Absolute Encoder

Product Lineup

Actuator Type |

Driver Type |

Power Supply |

Available Options |

Thrust Force |

Stroke |

||

42 mm (1.65 in.) Linear Actuator with Guide |

24/48 VDC |

Electromagnetic Brake |

50 N 200 N |

11.2 lb 45 lb |

40 mm |

1.57 in. |

|

42 mm (1.65 in.) Linear Actuator |

24/48 VDC |

Electromagnetic Brake |

50 N 200 N |

11.2 lb 45 lb |

40 mm |

1.57 in. |

|

60 mm (2.36 in.) Linear Actuator |

24/48 VDC |

Electromagnetic Brake |

500 N |

112 lb |

50 mm |

1.97 in. |

|

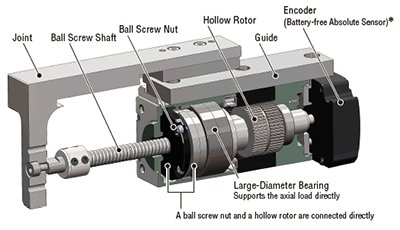

Compact Linear Actuators

Reliable Design and Structure

A hollow rotor and a ball screw nut are joined. Since no connecting parts are necessary, there is less backlash than when coupling rigidity, etc. combines other parts. Therefore, highly accurate positioning can be achieved.

High Positioning Accuracy

The ball screw nut is linked with the hollow rotor. Through the coupling rigidity and other aspects of parts combination, the impact of backlash has been minimized achieving high-precision positioning.

Ground Ball Screw

Ideal for applications where high positioning accuracy and low vibration are required, such as optical devices and semiconductor systems that use fine-feed pitches. The DRS ground ball screw type achieves high reliability by maximizing the performance of a 5-phase stepper motor.

Rolled Ball Screw

Ideal for general positioning applications where reliability and ease of use are given priority. It combines the superior thrust and resolution of the ground ball screw type with greater ease of use.

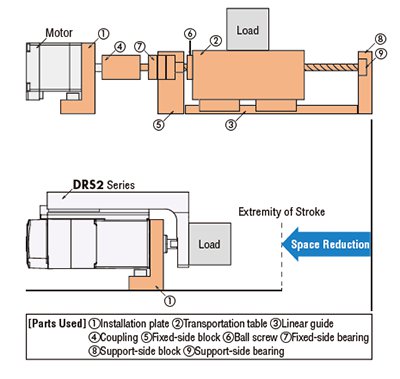

Compact Body Houses Entire Linear Motion Mechanism

Since customers do not need to provide parts, the time needed for installing, designing, and selecting parts can be reduced. The number of man-hours required for assembly and adjusting the installation accuracy can be reduced, contributing to higher productivity.

Installation Time Reduced

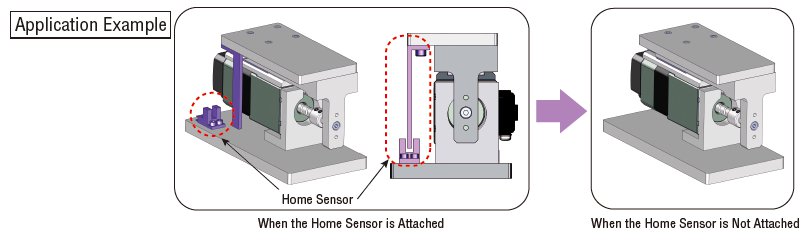

Space Saving and Less Wiring with the Absolute Sensor

In addition to the compact and lightweight body, the motors with absolute sensors do not require a home sensor. This saves space and wiring, and lets you avoid routine maintenance or trouble caused by using a home sensor.

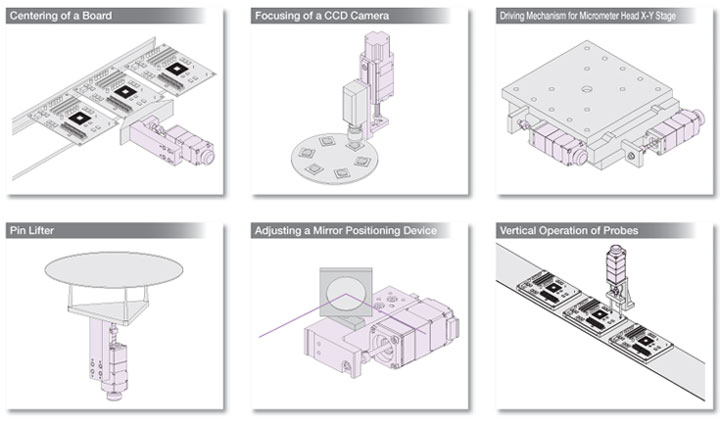

Application Examples

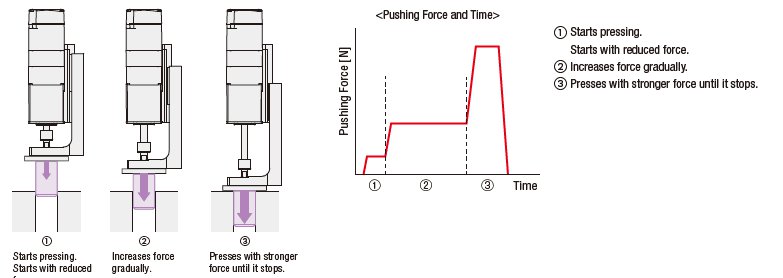

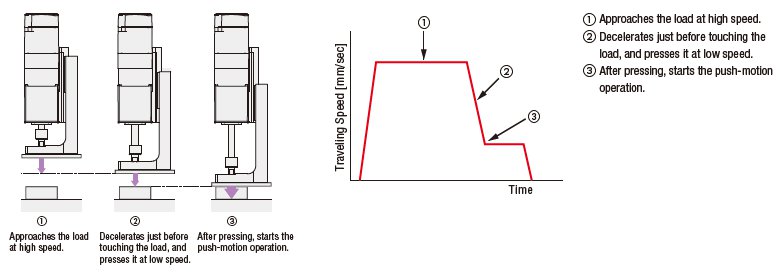

Efficient Push-Motion Operation

Flexible Pushing Force and Timing

The DRS2 Series can easily perform a push-motion operation after a positioning operation. Also, the pushing force and timing are adjustable.

- You can set the pushing force and push timing to an operation data No., and then select the data No. to change the settings.

- There are different ways to change the pressing phases, such as dropping the force so that the position does not shift, slowly increasing

the force, or rapidly increasing the force.

Pressing at Low Speed

The motor can approach the load at high speed. The motor decelerates just before hitting the surface at low speed.

- Since the pressing impact is minimal, a mechanism for shock absorption is not required.

- The motor can approach at high speed just before reaching the surface, thus reducing the takt time.

Push-Motion Operation with Pulse Input Type

When T-MODE input is set, push-motion operation is possible, without the overload alarm for the pulse input type being generated.

This is useful for push-motion operation while using pulse signal control.

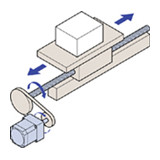

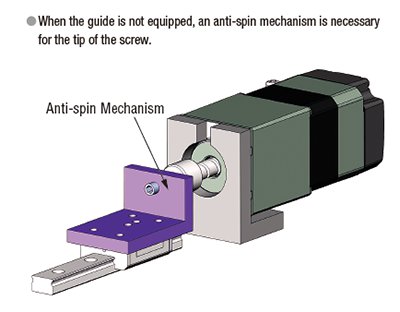

Guide Type

- 42 mm (1.65 in.)

Compact linear actuators with built-in guide reduces the need for an external anti-spin mechanism further reducing parts required for designing your applications.

High Transportable Mass and High Speed are Achieved

Maximum Transportable Mass

- Horizontal direction: 10 kg [Lead 2 mm], 5 kg [Lead 8 mm]

- Vertical direction: 10 kg [Lead 2 mm], 5 kg [Lead 8 mm]

Maximum Speed

- 50 mm/sec [Lead 2 mm], 200 mm/s [Lead 8 mm]

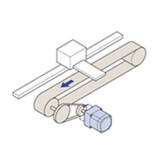

Standard Type

- 42 mm (1.65 in.)

- 60 mm (2.36 in.)

The standard compact linear actuators, no guide type, require the use of an Anti-spin Mechanism

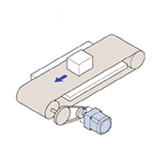

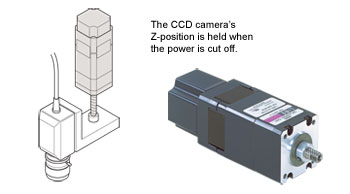

Electromagnetic Brake

- 42 mm (1.65 in.)

- 60 mm (2.36 in.)

The load position can be held when the power is cut off. Since the work will not fall in case of power failure or disconnection, you can safely use equipment in which the work moves vertically.

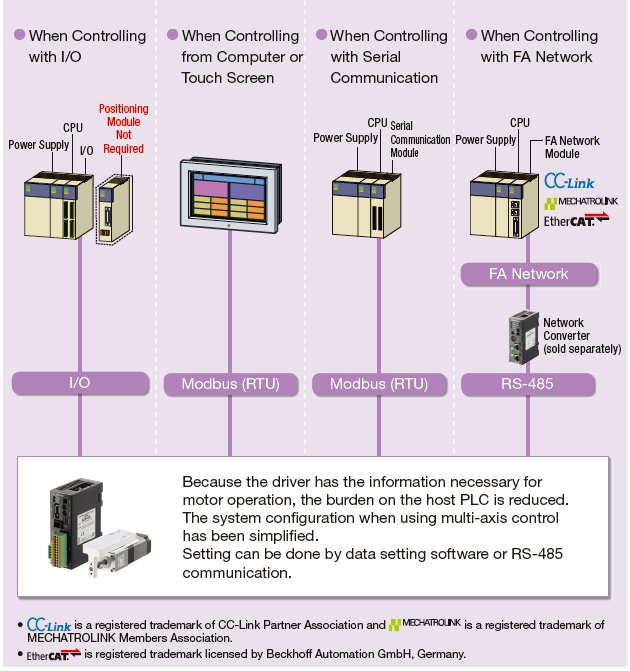

Built-in Controller (Network Type)

1. I/O

Because the positioning unit (pulse generator) function is built in to the driver, you can build an operation system using I/O by directly connecting to a switch box or PLC. Because a positioning unit is not necessary on the PLC side, space is saved and the system is simplified.

Using a Switch Box - Because operating data is set in the driver, the actuator can be started and stopped simply by connecting a switch you have on hand. Control can be performed easily without using PLC.

Using PLC - When using PLC you can build an operation system by connecting directly to an I/O unit. Because a positioning unit is not necessary on the PLC side, space is saved and the system is simplified.

Using PLC and a Touch Screen - Normally, the actuator is started and stopped with I/O. Changing the operating data settings and displaying the monitors and alarms is performed with the touch screen using Modbus (RTU) communication. When there is a lot of setup work, changes can be easily performed on the touch screen, and the burden of creating ladders is reduced.

2. Modbus (RTU) / RS-485

Operating data and parameters can be set and operation commands can be input using RS-485 communication. Up to 31 drivers can be connected to each serial communication unit. Also, there is a function that enables the simultaneous start of multiple axes. The protocol supports Modbus (RTU), enabling connection with devices such as touch-screen panel computers and PCs.

3. Industrial Network

Using a network converter (sold separately) enables support with EtherCAT communication, CC-Link communication, and MECHATROLINK communication. Operating data and parameters can be set and operating commands can be input using various communication methods.

AZ Series Absolute Sensor Stepper Motor

Newly Developed Absolute Sensor

Oriental Motor has developed a compact, low-cost, battery-free mechanical type absolute sensor (patented). This can help improve productivity and reduce costs.

Mechanical-Type Sensor

A mechanical sensor composed of multiple gears is employed. Positioning information is detected by recognizing the angle of the individual gears.

Multi-turn absolute sensor

Absolute position detection is possible with ±900 rotations (1800 rotations) of the motor shaft from the reference home position.

Home Setting Method

The home position can be easily set by pressing a switch on the driver's surface, which is saved by the Absolute Sensor. In addition, home setting is possible with the data setting software (MEXE02) or by using an external input signal.

Battery-free

No battery is required thanks to a mechanical-type sensor. Positioning information is managed mechanically by the absolute sensor.

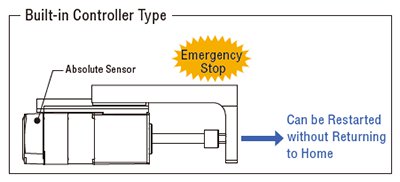

Holding Positioning Information

Even if the power shuts down during a positioning operation or

the cable between the actuator and the driver is disconnected,

the positioning information is retained. With the built-in controller

type, you can restart the positioning operation, without performing

return-to-home after an emergency stop on the production line or

a blackout.

Reduced Maintenance

Because there is no battery that needs replacing, maintenance time and costs can be reduced.

Unlimited Driver Installation Possibilities

Because there is no need to secure space for battery replacement, there are no restrictions on the installation location of the driver, improving the flexibility and freedom of the layout design of the control cabinet.

Safe for Overseas Shipping

Normal batteries will self-discharge, so care must be taken when the equipment requires a long shipping time, such as when being sent overseas. The Absolute Sensor does not require a battery, so there is no limit as to how long the positioning information is maintained. In addition, there is no need to worry about various safety regulations, which must be taken into consideration when shipping a battery overseas.

No External Sensors Required

With the use of the absolute system, external sensors such as the home sensor and the limit sensor are not needed.

High Speed Return-to-Home

Because return-to-home is possible without using an external sensor, return-to-home can be performed at high speed without taking the specifications for sensor sensitivity into account, allowing for a shortened machine cycle.

Reduced Cost

Sensor costs and wiring costs can be reduced, allowing for lower system costs.

Simple Wiring

Wiring is simplified, and the degree of freedom for equipment design is increased.

Not Affected by External Sensor Malfunctions

There is no need for concern about sensor malfunctions, sensor failures, or sensor wire disconnections.

Improved Return-to-Home Accuracy

Home position accuracy is increased because the return-to-home operation is performed regardless of any variations in home sensor sensitivity.

*If no limit sensor is installed, movements that exceed the limit values can be avoided through the use of the limits in the driver software.

Network Gateways

The communication protocol of the master controller, Factory Automation (FA) network, is converted to Oriental Motor's own RS-485 communication protocol. Connection to Oriental Motor's network compatible products is completed with one RS-485 communication cable.

- Compatible Networks:

CC-Link, MECHATROLINK-II, MECHATROLINK-III, EtherCat

*For use with Stored Data (Network) type

![]()

![]()

![]()

SCX11 Universal Controller

The SCX11 is a highly-functional and sophisticated controller equipped with program editing and execution functions. Use the SCX11 as a stored program controller to connect to any of Oriental Motor's standard pulse input drivers. The SCX11 is also able to control the motor via serial communications such as USB, RS-232C and CANopen.

*For use with Pulse Input Type driver.

RS-485 Communication Cable

These cables are used to link drivers when a built-in controller type is being operated in a multi-drop manner.

*For use with Stored Data (Network) type and Pulse Input Type with RS-485 Communication

Cables for Single-Axis Drivers

These cables are used to connect or extend the distance between the motor and single-axis driver.

Required (sold separately).

Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

*Multi-Axis Controller / Driver requires different cables

Control Options - Data Setting Software

MEXE02 Data Setting Software.

*A standard USB to mini B cable is used to connect all drive options to the computer (sold by a third party).

Mounting Plate

A dedicated mounting bracket for installation of the DRL Series actuator. Each mounting plate comes with mounting screws for fastening the actuator to the plate.

Model |

Applicable Product |

DRSM42 |

|

DRSM60 |

General Purpose Cables

This is a shielded cable equipped with a half-pitch connector at one end of the cable that snaps onto the driver. The other end is laminated lead wires aligned in order at a pitch of 0.05 in. (1.27 mm), which is convenient for insulation displacement connectors.

Item |

Length |

3.3 ft. (1 m) |

|

6.6 ft. (2 m) |

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.